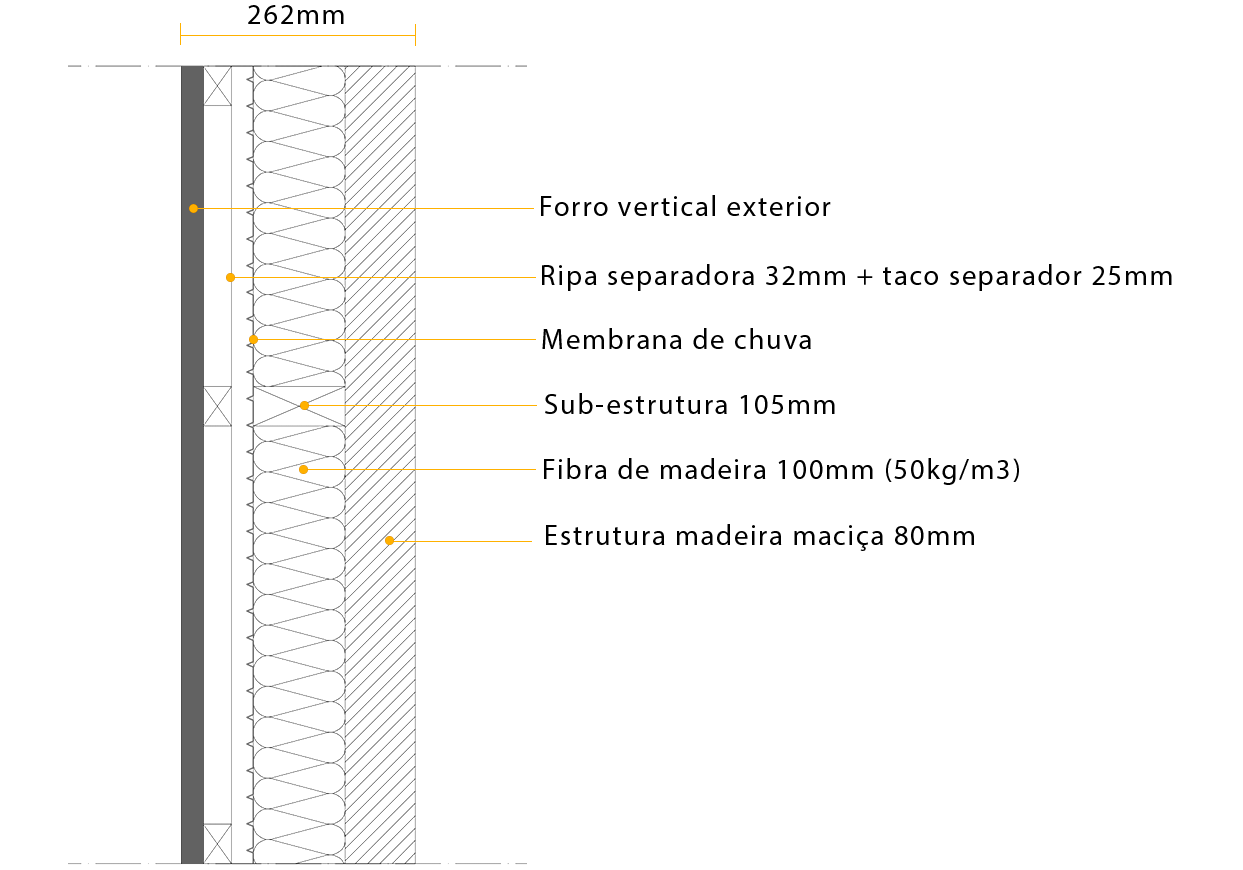

PRIMARY: Solid Japanese cedar wood pieces, 80 mm thick, laminated and glued, positioned vertically or horizontally, form the primary structure of the walls, supporting the upper loads of the intermediate slab and roof.

The pieces fit together with tongue and groove joints and are fastened with structural screws.

This solid wood wall, which forms the interior facing of the house, is prepared with holes for the electrical wiring and air ventilation ducts (CMV).

SECONDARY: A second structure, fixed to the back of the first with structural screws, consists of 100x40mm studs and crossbars, spaced 600mm apart, forming a technical box to house the thermal insulation and the electrical and ventilation networks.

A breathable rain barrier membrane is placed over the thermal insulation supplement.

Water vapour migration from inside to outside the house is based on the principle of a breathable wall, without the use of a vapour barrier membrane.

Japanese cedar wood (80 mm) is an insulator that meets part of the building's thermal requirements.

A strip of flax fibre is applied to the tongue-and-groove joint of each piece.

The wall's thermal insulation is complemented by 100 mm of wood fibre, placed in the space of the secondary structure.

VENTILATED FACADE: The exterior cladding consists of a 20 mm thick openwork lining of Japanese cedar wood, fixed to support slats.

Blue like the sea, green like the countryside, white like the clouds or natural like wood. Colours allow you to personalise your home and integrate it into the surrounding landscape. This is the case with this house, which alludes to the coastline. With around 240m2 of built area, of which 224m2 are habitable and more than 15m2 are porches, this elegant house was designed to house 2 to 3 bedrooms, one of them on a mezzanine level that can also be used as a multipurpose room. The living room, dining room and kitchen form a large open space of around 45m2 plus a utility room and technical room of 10m2.

*Basic price subject to confirmation. Includes assembly of the wooden structure up to 100km from the factory. VAT not included. Contact us for more information.

BUILT-UP AREA: 240 M2

.webp)

.webp)

When designing your home, the only limit is your dreams. This could well be it. A 114m2 two-bedroom house with large glazed areas that let light into the interior and allow you to contemplate the landscapes outside. Although relatively small in size, this house has everything to guarantee the utmost comfort. A very large open area of over 50m2 forms the social space of the house, with the living room and dining room joined to the kitchen, only separated by an island, and a small office or reading or TV area discreetly hidden by the fireplace or wood burning stove. A technical room allows us to place the machines and installations we want to keep hidden.

*Basic price subject to confirmation. Includes assembly of the wooden structure up to 100km from the factory. VAT not included. Contact us for more information.

BUILT-UP AREA: 114 M2

.webp)

.webp)

Ideal for large families, this spacious 300m2 house offers the necessary space to accommodate 4 bedrooms with a luxury suite and 3 full bathrooms. The communal area is open-plan around the living and dining room, kitchen and area reserved for a library, TV corner or office, all in 80m2. The numerous storage rooms, walk-in wardrobes, built-in cupboards, pantry and laundry room complete the interior of the house with 226.50m2 of living space. There are also two generous 65m2 porches in the entrance, bedrooms and living room areas and an 8.50m2 pergola that gives access to the laundry room.

*Basic price subject to confirmation. Includes assembly of the wooden structure up to 100km from the factory. VAT not included. Contact us for more information.

BUILT-UP AREA: 300 M2

Use of cookies

Our website uses cookies to improve the browsing experience and for statistical purposes. For more information, please consult our Cookie Policy