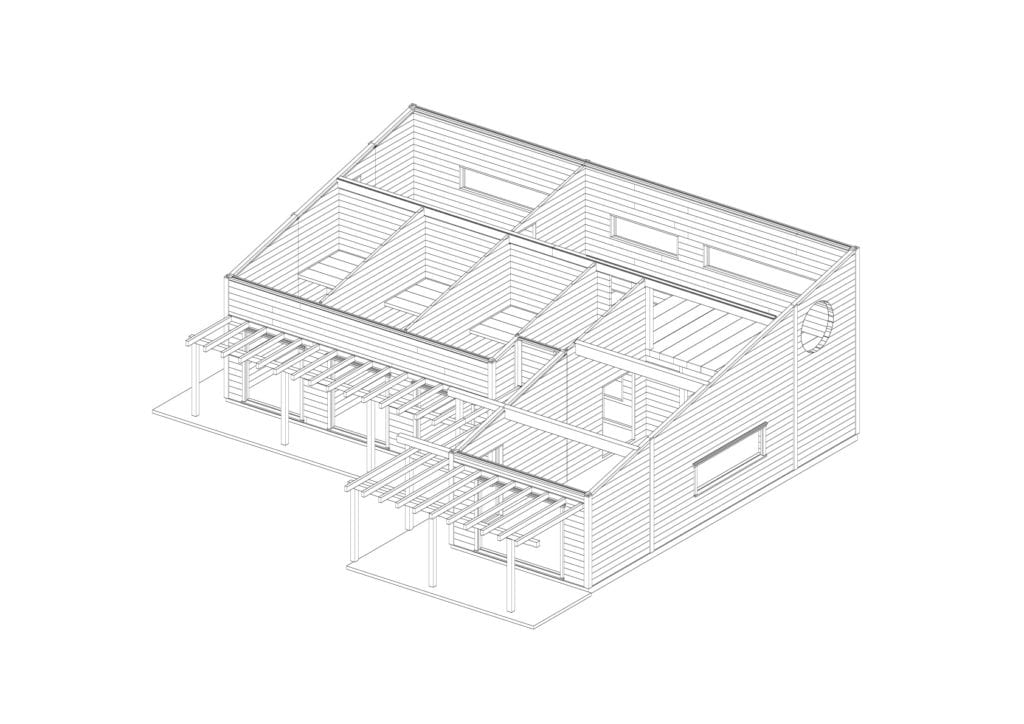

For big families, big solutions! Two bedrooms and two suites, one of them on the upper floor with private living room over mezzanine, and a social area with open kitchen

![]() The Insulated Timber System (ITS™) uses NATURLAM® self-supporting panels for all structural and house-covering elements. The glued laminated wood panels insulated with cork at its core, offer a high coefficient of thermal resistance and allow a very fast assembly.

The Insulated Timber System (ITS™) uses NATURLAM® self-supporting panels for all structural and house-covering elements. The glued laminated wood panels insulated with cork at its core, offer a high coefficient of thermal resistance and allow a very fast assembly.

ITS™ is born from the conjunction of the log house constructive technique with the Timber Frame system. In addition to reconstituting the log with glued laminated wood, adding cork in its core to increase its thermal performance, the pieces are joined together to form self-supporting structural panels, thus giving the constructive system unmatched benefits, both in terms of insulation and for its fast construction (2 days for walls and roof assembly).

ITS™ houses, mounted on both sides of the finished walls, can be delivered fully equipped, including exterior carpentry, as well as the channels for built-in electrical installation, offering a rapid execution time without setting or drying times, characteristic of the construction with wet conglomerates (traditional construction).

The reduced thickness of its walls optimizes the living space (+/- 8% more than in bricks), and increases the comfort of its occupants, thanks to the naturally perspirable materials that regulate the interior humidity, with low thermal inertia and the absence of thermal bridges (+/- 30% of heat loss in traditional construction).

House in Vila Verde