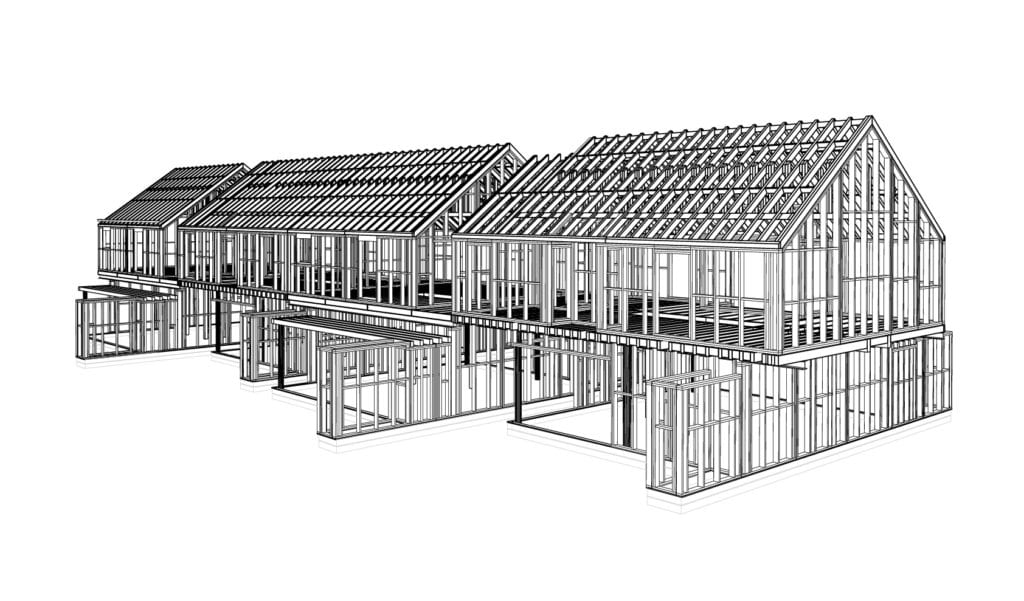

Suitable for any type of terrain (landlocked, small, unstable, sloping…), the Timber Frame structure is up to 7 times lighter than a concrete construction and 17 times lighter than steel,

In timber construction, the Timber Frame system is the most widely used construction technique, allowing great freedom of architectural expression.

In timber construction, the Timber Frame system is the most widely used construction technique, allowing great freedom of architectural expression.

It is ideal for both new constructions and extensions. A house in Timber Frame combines lightness and sturdiness.

Depending on the degree of prefabrication, our Timber Frame constructions can be delivered fully equipped, with exterior carpentry and included coatings, offering a speed of execution without setting or drying times characteristic of the construction with wet conglomerates (conventional construction).

The reduced thickness of its walls optimizes the living space (+/- 8% more than in bricks), besides increasing the comfort of its occupants, thanks to insulating materials that regulate the interior humidity, with low thermal inertia and absence of thermal bridges (+/- 30% of heat losses in traditional construction).

Suitable for any type of site (landlocked lot, narrow, unstable, steeply sloped, …), a wood frame construction is up to 7 times lighter than a concrete construction and 17 times lighter than steel, requiring much less substantial and less expensive foundations and is suitable for low lift fields, or in poorly stabilized areas.

The solution to a dry, clean, fast and energy-efficient construction.

Timber Frame House in Arcos de Valdevez